Material: Self-locking tight nuts are typically made of metal, such as steel or stainless steel, providing strength, durability, and resistance to corrosion.

Design: Self-locking tight nuts feature a specialized design that incorporates a locking mechanism, such as a nylon insert, metal insert, or serrated flange, which helps to prevent the nut from loosening under vibration or other external forces.

Types: Self-locking tight nuts come in various types, such as hexagon nuts, flange nuts, nylon lock nuts, metal lock nuts, or prevailing torque nuts, among others, each with its unique locking mechanism and features.

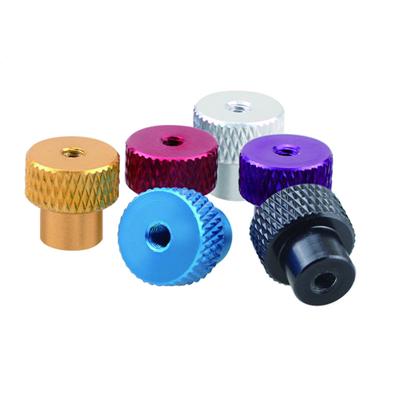

Finish: Self-locking tight nuts may come in a plain or plated finish, such as zinc plating, nickel plating, or other coatings, to enhance corrosion resistance and appearance.

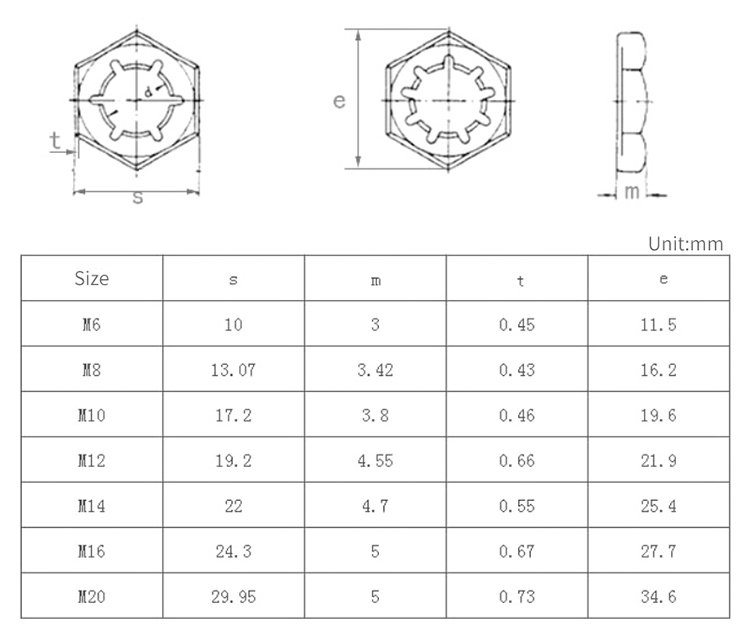

Size: Self-locking tight nuts are available in different sizes, thread types, and configurations to accommodate various bolt sizes, thread pitches, and applications.

Fields of Application:

Automotive and Transportation: Self-locking tight nuts are commonly used in the automotive and transportation industries for securing critical components, such as engines, transmissions, suspensions, or exhaust systems, where vibrations and other dynamic forces can cause traditional nuts to come loose.

Industrial and Manufacturing: Self-locking tight nuts are widely used in industrial and manufacturing applications where reliable and secure fastening is required. They can be used in applications such as machinery, equipment, structural assemblies, or heavy-duty installations, where vibrations, impacts, or external forces may cause regular nuts to loosen over time.

Aerospace and Aviation: Self-locking tight nuts are used in aerospace and aviation applications where safety and reliability are paramount. They are commonly used in aircraft engines, landing gear, flight control systems, or other critical components where the prevention of fastener loosening is essential for safe operation.

Construction and Building: Self-locking tight nuts can be used in construction and building applications for securing structural elements, steel beams, or other critical connections that require reliable and long-lasting fastening. They are also used in HVAC systems, plumbing, or electrical installations, where vibrations or movements may cause regular nuts to come loose.

Machinery and Equipment: Self-locking tight nuts are utilized in machinery and equipment manufacturing for securing components, assemblies, or subsystems that are subjected to constant vibrations, impacts, or dynamic forces. They can be used in applications such as industrial machinery, agricultural equipment, or heavy-duty vehicles, where maintaining tight and secure fasteners is crucial for efficient and safe operation.

Marine and Offshore: Self-locking tight nuts are commonly used in marine and offshore applications where saltwater exposure, vibrations, and harsh environmental conditions can cause regular nuts to come loose. They are used in marine vessels, offshore platforms, or underwater equipment, where reliable and durable fastening is required to ensure safe and efficient operation.