Flat head rivets, also known as countersunk rivets, are a type of rivet with a flat or countersunk head that sits flush or slightly below the surface of the material being joined. They are typically used in applications where a smooth and aesthetically pleasing finish is desired, and where the head of the rivet should not protrude above the material surface. Here are some common product details of flat head rivets:

Material: Flat head rivets are made from various materials, including aluminum, steel, stainless steel, and brass. The material selection depends on the specific application requirements, such as the material being joined, the environment in which the rivet will be used, and the desired strength and corrosion resistance of the joint.

Head Style: Flat head rivets have a flat or countersunk head that sits flush or slightly below the surface of the material being joined. The head style allows for a smooth and aesthetically pleasing finish, making them suitable for applications where appearance is important.

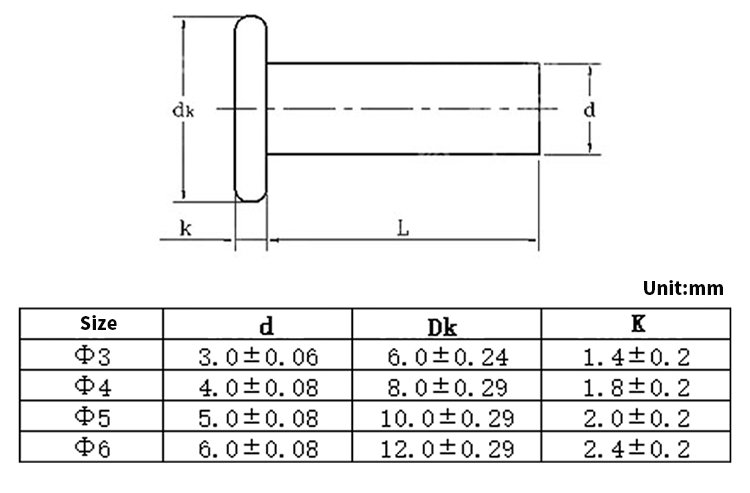

Body Diameter: Flat head rivets come in various body diameters, ranging from small to large, to accommodate different application requirements. The body diameter determines the strength and load-carrying capacity of the rivet and should be selected based on the specific application requirements.

Grip Range: Flat head rivets come in various grip ranges, which represent the maximum material thickness that can be effectively joined by the rivet. The grip range is critical to ensuring a proper joint formation and should be selected carefully to avoid insufficient or excessive grip.

Mandrel Diameter: Flat head rivets come with different mandrel diameters, which determine the strength and performance of the rivet during installation. The mandrel diameter should be selected based on the specific application requirements and the desired strength of the joint.

Fields of Application:

Flat head rivets are widely used in various industries and applications where a flush or countersunk finish is desired, and where a smooth and aesthetically pleasing appearance is important. Some common fields of application for flat head rivets include:

Automotive and transportation: Flat head rivets are used in the automotive and transportation industry for joining components such as body panels, interior trim, and decorative elements. The flush or countersunk head of the rivet provides a smooth and seamless finish, enhancing the appearance of the finished product.

Aerospace and aviation: Flat head rivets are used in the aerospace and aviation industry for joining components such as panels, brackets, and access doors. The flush or countersunk head of the rivet minimizes aerodynamic drag and provides a smooth surface, which is important in aerospace applications where weight reduction and aerodynamic performance are critical factors.

Electronics and appliances: Flat head rivets are used in the electronics and appliances industry for joining components such as circuit boards, casings, and panels. The flush or countersunk head of the rivet provides a smooth and clean appearance, making them suitable for applications where aesthetics and appearance are important.

Furniture and woodworking: Flat head rivets are used in the furniture and woodworking industry for joining materials such as wood, plywood, and laminates. The flush or countersunk head of the rivet provides a smooth and seamless finish, making them ideal for applications where a clean and aesthetically pleasing appearance is desired.

General manufacturing and fabrication: Flat head rivets are used in general manufacturing and fabrication applications for joining materials in various industries, such as metal fabrication, signage, and industrial equipment. The flush or countersunk head of the rivet allows for a smooth and seamless finish, making them suitable for applications where appearance and aesthetics are important.