Semi-tubular rivets, also known as tubular rivets or hollow rivets, are a type of rivet that has a tubular or hollow body with a solid head on one end and a partially formed tail on the other end. Here are some common product details of semi-tubular rivets:

Material: Semi-tubular rivets are typically made from materials such as steel, brass, aluminum, or stainless steel, depending on the specific application requirements. The material selection depends on factors such as the materials being joined, environmental conditions, and desired strength and appearance of the joint.

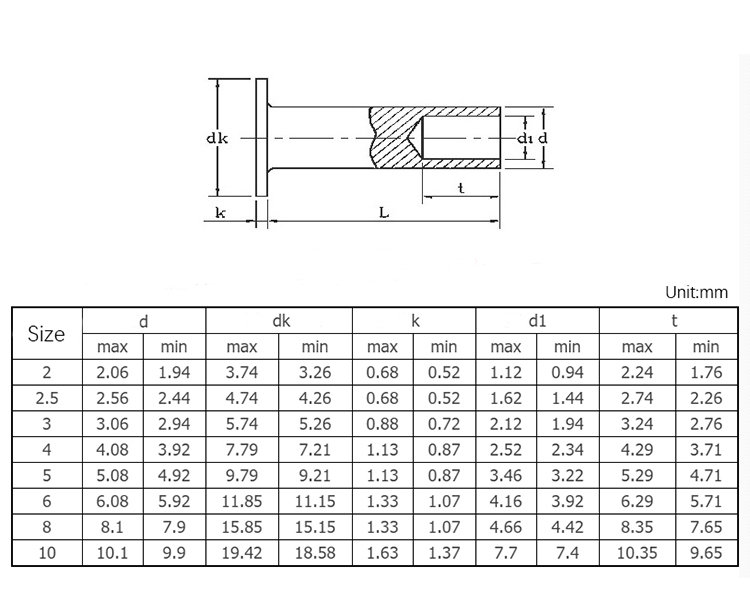

Size: Semi-tubular rivets come in different sizes, with varying body diameters and lengths, to accommodate different material thicknesses and application requirements. The size of the rivet should be selected based on the specific materials being joined and the desired strength of the joint.

Head Style: Semi-tubular rivets have a solid head on one end that can be round, oval, or countersunk, depending on the desired appearance and tooling requirements. The head is typically larger than the body diameter and provides a surface for applying pressure during installation.

Tail Type: Semi-tubular rivets have a partially formed tail on the other end that is used to create a permanent joint. The tail can be bent, clinched, or peened over to secure the rivet in place and create a strong and durable joint.

Installation Method: Semi-tubular rivets are typically installed using a rivet tool or a hand rivet setter. The installation process involves inserting the rivet into the pre-drilled holes of the materials to be joined, applying pressure to the head, and then deforming the tail to create a secure and permanent joint.

Fields of Application:

Semi-tubular rivets are commonly used in various industries and applications where a fast and efficient method of joining materials is required. Some common fields of application for semi-tubular rivets include:

Automotive and transportation: Semi-tubular rivets are used in the automotive and transportation industry for joining various components, such as sheet metal, brackets, and panels. They provide a quick and reliable method of fastening that can be used in tight spaces or where access to the backside of the materials is limited.

Electronics and appliances: Semi-tubular rivets are used in the electronics and appliances industry for joining components, such as cases, chassis, and brackets. They provide a secure and durable joint without the need for additional fasteners or adhesives, making them suitable for applications where reliability is critical.

Furniture and woodworking: Semi-tubular rivets are used in furniture and woodworking applications for joining wood or composite materials, such as chairs, cabinets, and frames. They provide a fast and efficient method of fastening that can be used in both structural and decorative applications.

Sports equipment and recreational products: Semi-tubular rivets are used in the manufacturing of sports equipment and recreational products, such as bicycles, skateboards, and camping gear. They provide a lightweight and durable fastening solution that can withstand the rigors of outdoor and sports-related activities.

Metal fabrication: Semi-tubular rivets are used in metal fabrication applications for joining metal components, such as sheet metal, panels, and brackets. They provide a quick and efficient fastening method that does not require welding or other time-consuming processes, making them suitable for high-volume production environments.

Aerospace and aviation: Semi-tubular rivets are used in the aerospace and aviation industry for joining structural components, such as panels, brackets, and frames. They provide a lightweight and reliable method of fastening that meets the stringent requirements of aerospace and aviation applications.