Countersunk head rivets, also known as flush head rivets or flat head rivets, are a type of rivet that feature a flat or flush head that sits flush with the surface of the materials being joined. They are typically used when a smooth and low-profile finish is desired. Here are some common product details of countersunk head rivets:

Material: Countersunk head rivets are made from various materials, such as aluminum, stainless steel, brass, or steel, depending on the specific application requirements. The material selection depends on factors such as the materials being joined, environmental conditions, and desired appearance.

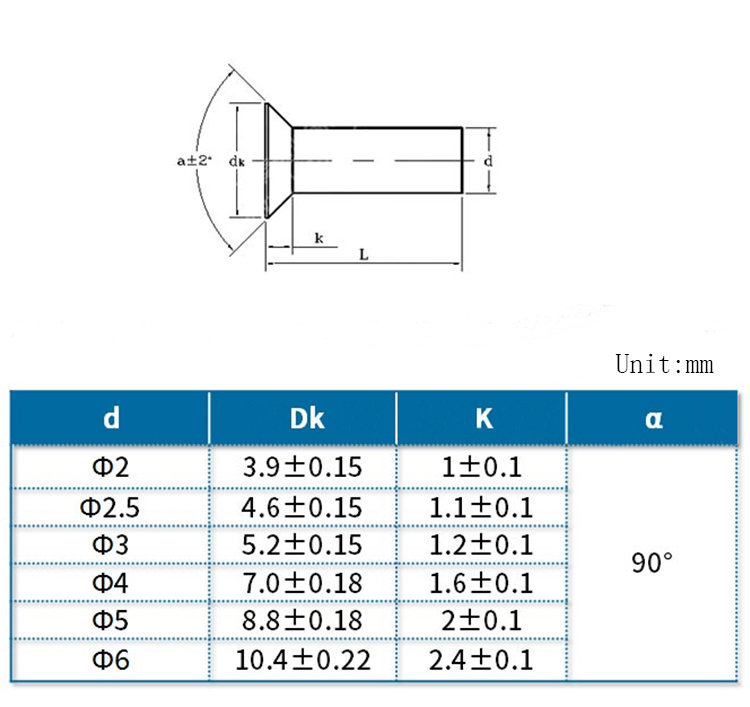

Size: Countersunk head rivets come in different sizes, with varying body diameters and lengths, to accommodate different material thicknesses and application requirements. The size of the rivet should be selected based on the specific materials being joined and the desired strength of the joint.

Head Style: Countersunk head rivets have a flat or flush head that sits flush with the surface of the materials being joined, creating a smooth and low-profile finish. The head may be slotted, Phillips, or other styles, depending on the desired appearance and tooling requirements.

Mandrel Type: Countersunk head rivets typically come with a solid mandrel or a hollow mandrel. Solid mandrels are used in applications where the rivet needs to provide additional strength, while hollow mandrels are used in applications where a non-ferrous mandrel is required for electrical conductivity or other specific purposes.

Installation Method: Countersunk head rivets are typically installed using a rivet tool or a hand rivet setter. The installation process involves inserting the rivet into the pre-drilled holes of the materials to be joined, applying pressure to the mandrel end, and pulling the mandrel through the rivet body until it breaks, creating a secure and permanent joint.

Fields of Application:

Countersunk head rivets are commonly used in various industries and applications where a flush and low-profile finish is desired, along with a reliable and durable fastening method. Some common fields of application for countersunk head rivets include:

Aerospace and aviation: Countersunk head rivets are used in aerospace and aviation applications where lightweight and high-strength fasteners are required. They are commonly used in the assembly of aircraft structures, panels, and components, where a flush finish is desired to reduce drag and enhance aerodynamics.

Automotive and transportation: Countersunk head rivets are used in the automotive and transportation industry for joining various components, such as body panels, trim pieces, interior components, and engine components. They provide a secure and low-profile fastening method that can withstand the rigors of automotive applications.

Construction and architecture: Countersunk head rivets are used in construction and architectural applications for joining metal or composite materials, such as curtain walls, claddings, facades, and structural elements. They provide a neat and flush finish that enhances the aesthetics of the building while providing reliable structural fastening.

Electronics and appliances: Countersunk head rivets are used in the electronics and appliances industry for joining components, such as cases, covers, brackets, and panels. They provide a low-profile and reliable fastening method that can be used for securing sensitive electronic components or appliances.

Marine and boat building: Countersunk head rivets are used in marine and boat building applications for joining various components, such as hulls, decks, and interior fittings. They provide a flush and corrosion-resistant fastening method that can withstand the harsh marine environment, including saltwater exposure and UV radiation.

Furniture and woodworking: Countersunk head rivets are used in furniture and woodworking applications for joining wood or composite materials.